.

.

Client: Burlington Medical

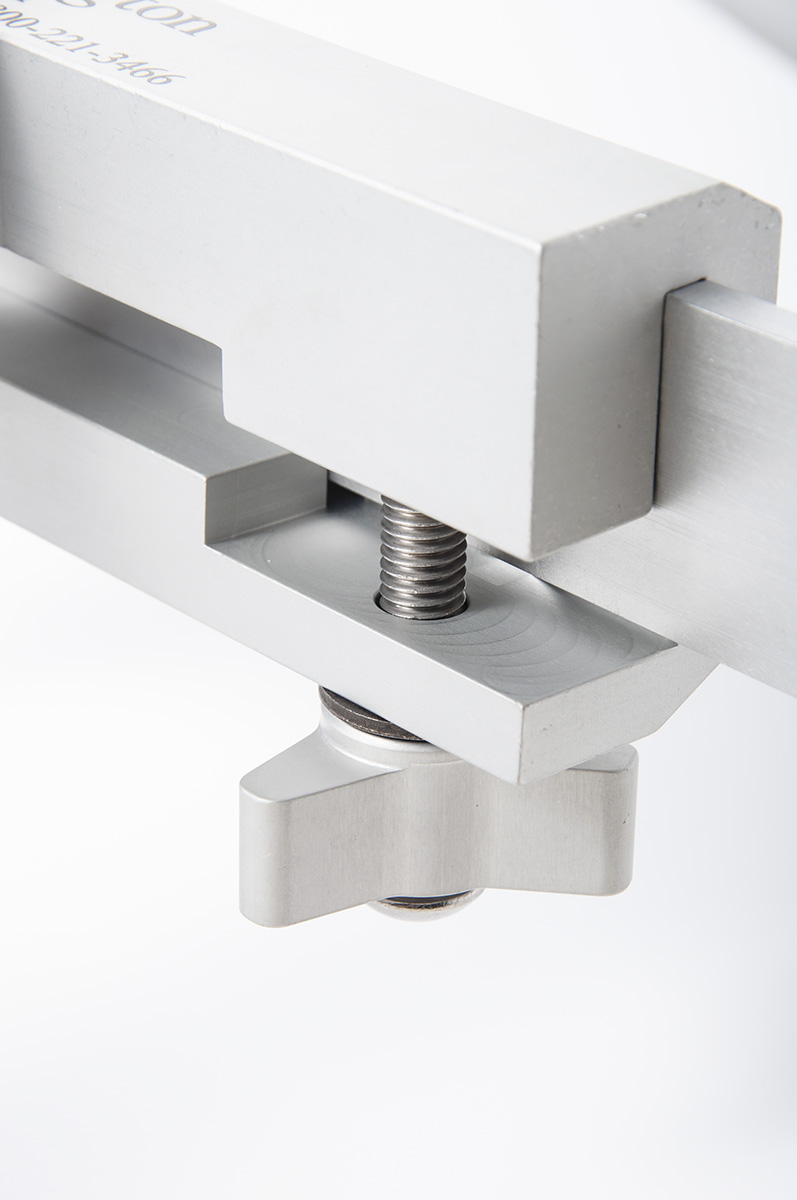

Project: CNC-manufactured Radiology Drape Arm

Turnkey Manufacturing, Aluminum Machining, Laser Engraving, Industrial Design

Burlington Medical came to us with a mechanical design problem.

They needed a specialized radiology drape arm, which is an adjustable support for mobile X-ray units that attaches to a wide variety of operating tables.

They came away with a complete design package & turnkey manufacturing partner.

The Challenge: Precision Engineering for a Complex Environment

Burlington Medical needed a drape-support arm that could:

Attach securely to numerous operating table rail sizes

Be quickly removable in emergencies

Articulate flexibly around the table’s shape

Function ambidextrously - usable on either side

Support ~20 lbs at a 36-inch full extension, with three articulating joints

These constraints demanded a rugged, adaptable design combining strength, precision and usability.

Results

Tektonics delivered a reliable, high-performance radiology drape arm meeting Burlington Medical’s strict operational standards.

As a lean manufacturer, we continue supplying Burlington Medical with dependable inventory - ready to support design revisions or updates as needed.

Contact Us

Curious how Tektonics can support your next medical device or precision-machined component?

Call: 804-233-5900

Email: info@tektonics.com

Address: Tektonics Design Group, 702 E. 4th St, Richmond, VA 23224

Reach out today for precision solutions tailored to your industry’s needs.

Our Solution: From Design to Production

Industrial Design & Engineering

Developed several iterations using mechanical-force analysis and field testing to ensure safe, ergonomic operation.

Finalized a complete design package-spanning clamps, arms, and custom-release hardware (specialty hinge bolts and fast-release knobs).

Turnkey Manufacturing

Transitioned seamlessly from design approval into full production using in-house CNC machining.

Components underwent a finishing process: tumbling, clear anodizing, laser engraving, and precision packaging.

Integrated custom-machined brass bushings and bolts to ensure tight tolerances and no sag, even under full load.

Why it matters

We have the capacity for precision machining of complex systems in medical environments.

Our shop delivers an all-in-one workflow: industrial design, engineering analysis, and full-scale manufacturing.

Tektonics had deep expertise in serving clients requiring small- to medium-volume, high-quality custom parts.

Laser Engraving Logo

CNC Machined Aluminum Component

Product Design

Mechanical Design Components